Selective Plating for the Marine Industry

Better on board. The question of protection, where and when it’s needed most.

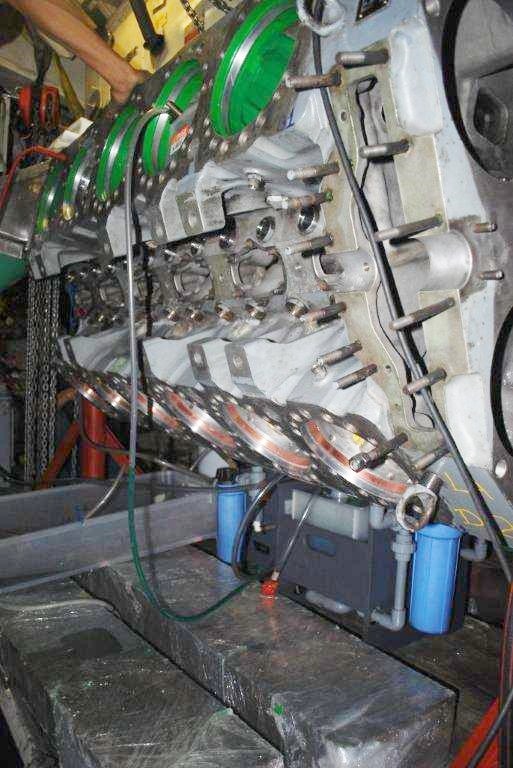

Our portable plating process can be taken on board ships for in-place repairs of large, difficult-to-move components such as bearing journals, propeller shafts, bearing seats, and turbine casings.

SIFCO Applied Surface Concepts is the global leader in the selective plating industry. The SIFCO Process® – a portable method to electroplate localized areas without the use of an immersion tank – is used for many different, demanding applications in the Marine industry. Our process does not require extensive masking and can minimize or eliminate the need for component disassembly.

Due to the significant time and cost savings it can offer in extending maintenance intervals and service life, selective plating plays a vital role on-board military and ABS-certified vessels. While the process can be used in the shop to repair worn bearing journals and housings on small generators, pumps and fans; it can also be taken aboard the ship for in-place repairs of large, hard to move, components such as propeller shafts, bearing seats, and turbine casings.

When timing is critical and you want it done right the first time, contact SIFCO ASC at one of our seven locations worldwide.

Chinese (Simplified)

Chinese (Simplified)  English (UK)

English (UK)  French

French  German

German  Spanish

Spanish  Swedish

Swedish