Improve process control, reduce turnaround time, improve safety, and increase productivity with SIFCO ASC’s automated plating systems.

From robotics to workstations, SIFCO ASC designs customized plating systems to electroplate or anodize localized areas on components. We provide full turnkey solutions that fit seamlessly into your operation.

With SIFCO ASC’s automated plating systems, we can help you meet OEM production specifications, have better control over your supply chain, and deliver improved visibility, traceability, and repeatability on plating requirements.

Automating your plating operation

Our technical design and project engineers will help create a tailored automated plating system customized to your exact requirements and objectives. Automated systems can be applied in almost any sector, including aerospace, power generation, marine, OEM production, electric motor and industrial engineering and manufacturing.

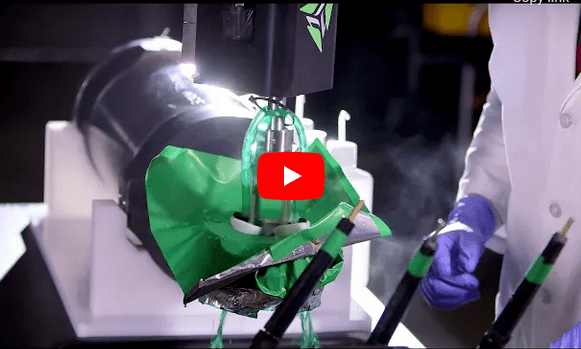

Watch our video on how we can automate your selective plating operation.

Chinese (Simplified)

Chinese (Simplified)  English (UK)

English (UK)  French

French  German

German  Spanish

Spanish  Swedish

Swedish